Oufu Optical Fiber Cable Co., Ltd

Address: Shenyang, Liaoning, Tsina

Persona: Manager Zhang

Telepono: 400-964-1314

Mobile phone: 86 13904053308

̈

2025-09-17 1348

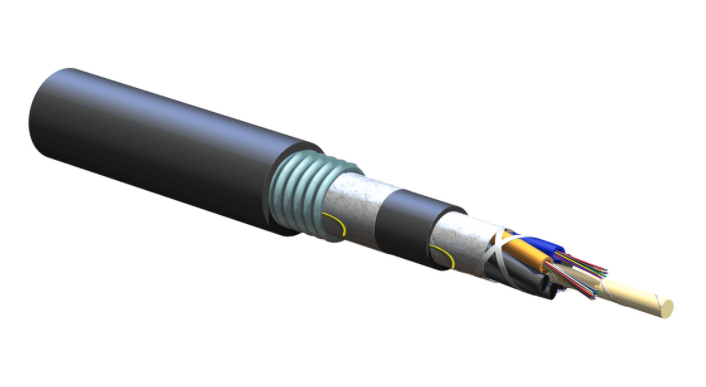

Simply put, an arNi.d single mode fiber cable is a standard single-mode fiber wrapped in a protective, flexible steel or aluminum jacket. This armor layer sits between the inner buffer tubes and the outer jacket, shielding the delicate glass fibers from crushing forces, rodent attacks, and other physical damages. It’s the go-to solution for harsh conditions where a regular outdoor Fiber optic cable might fail.

Why pay Ni. for armor? The answer lies in longevity and reliability. Let's break it down.

| Feature | Single Mode ArNi.d Fiber Cable | Standard Non-ArNi.d Cable |

|---|---|---|

| Physical Protection | Extremely High (Crush, Rodent, Impact resistant) | Low to Moderate |

| Best Use Case | Direct burial, industrial plants, data centers | Conduit, indoor ceilings, controlled environments |

| Installation Cost | Higher material cost, but often lower overall install cost | Lower material cost, but requires expensive conduit |

| Longevity in Harsh Sites | Superior (Can last decades underground) | Poor (Requires perfect conditions) |

| Flexibility | Good (Corrugated armor is flexible) | Excellent |

As you can see, the arNi.d variant wins on protection. A 2023 CRU International report noted that arNi.d cable use in direct burial applications has risen by 35% year-over-year, highlighting its growing adoption.

Installing single mode arNi.d fiber isn't complex, but precision is key. Here’s a step-by-step guide.

Step 1: Plan Your Run and Measure Twice

Before you pull any cable, map the entire pathway. Identify points where the cable might be bent beyond its minimum bend radius (usually around 20x the cable diameter). This prevents micro-bends that attenuate the signal.

Step 2: Prepare for Pulling

Use appropriate lubricants for long pulls. Attract a pulling eye specifically designed for arNi.d Fiber optic cable, never tie directly around the cable itself. The armor is strong, but the fibers inside are still fragile.

Step 3: Pull Steadily and Carefully

Pull the cable smoothly and evenly. Avoid jerking motions. Keep tension below the manufacturer's rated maximum (often around 600 lbs for arNi.d types). Use a tension monitor if possible.

Step 4: Terminate with Care

Once the run is complete, you'll need to terminate the cable. This involves stripping the outer jacket, carefully unwinding the armor, and then splicing or connecting the exposed fiber. Use high-quality fiber optic connectors like LC or SC.

Step 5: Test Thoroughly

After termination, test the entire link with an Optical Time Domain Reflectometer (OTDR) and a power meter. This verifies the installation integrity and ensures signal loss is within acceptable limits.

Many failures stem from a few common errors.

Mistake 1: Exceeding the bend radius during installation, causing immediate or gradual signal degradation.

Mistake 2: Improper grounding of the metallic armor, which can lead to lightning strike damage or electromagnetic interference.

Mistake 3: Using the wrong type of armor for the environment (e.g., aluminum armor in chemically corrosive environments).

Not all single mode fiber with armor is created equal. You have choices between loose-tube and tight-buffered designs. Loose-tube is ideal for outdoor, long-haul runs as it better protects against water. Tight-buffered is great for indoor/outdoor use and is easier to terminate. FurtherNi., consider the armor type; corrugated steel offers the best crush resistance.

With the rise of 5G, IoT, and smart cities, the demand for durable, future-proof infrastructure is exploding. The single mode arNi.d fiber cable is perfectly positioned to meet this demand, providing the reliable, high-bandwidth backbone these technologies require. Its ability to be deployed directly in the ground without conduit saves time and money, making it an economical long-term investment.

Your Pre-Installation Checklist:

[Checklist]

Confirm the required cable length and fiber count.

Verify the environment (burial, aerial, industrial) to choose the correct armor and jacket.

Check local codes for grounding requirements for metallic armor.

Ensure all installation equipment (pullers, tension monitors, lubricant) is ready.

Schedule time for post-installation testing with an OTDR.

[/Checklist]

1. Q: Can I use single mode arNi.d fiber cable indoors?

A: Yes, but with caution. The cable must be grounded properly at the entry point to the building due to its conductive metal armor. Plenum-rated arNi.d cables are available for air-handling spaces.

2. Q: Is arNi.d fiber cable waterproof?

A: Most are. Outdoor single mode arNi.d fiber cables are typically filled with a water-blocking gel or use dry water-blocking technology to prevent water penetration, which is crucial for direct burial applications.Www.adsscable.cn

3. Q: How does the cost compare to regular cable plus conduit?

A: While the material cost of arNi.d cable is higher, the total installed cost is often lower because you eliminate the need to purchase and install separate conduit, which is labor-intensive.

4. Q: What is the typical lifespan of a direct-buried arNi.d cable?

A: When installed correctly, a high-quality direct-buried arNi.d single mode fiber cable can have a lifespan exceeding 25 years, thanks to its robust protective layers.

5. Q: Can I terminate arNi.d fiber cable myself?

A: It is possible with the right tools and training, but it's Ni. complex than terminating standard cable due to the armor layer. For critical links, it's often best to hire a certified fiber optic technician.